| Key Dimensions 关键特征 |

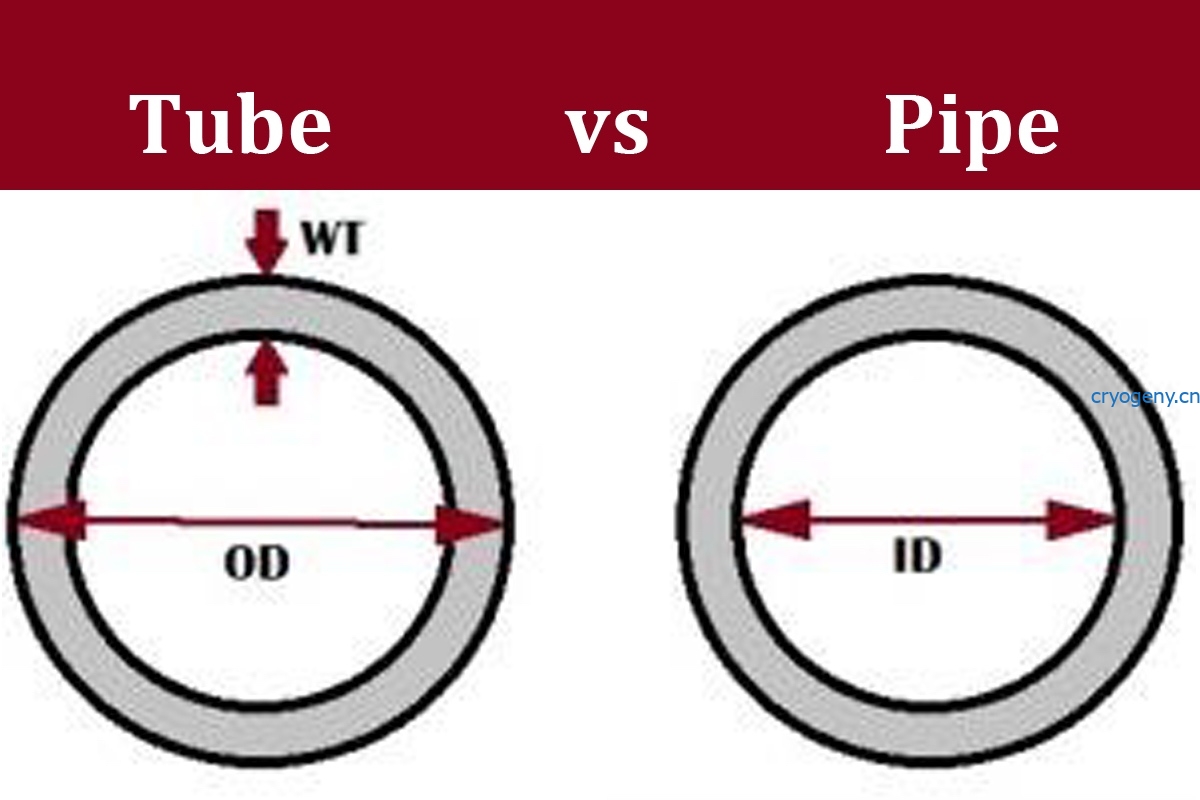

管的最重要的特征是外径和壁厚。外径减去两倍的壁厚得到内径。而内径决定了管能通过流体的能力。其公称管径与实际直径并不一致,只是一个粗略的指标。The most important dimensions for a pipe is the outer diameter (OD) together with the wall thickness (WT). OD minus 2 times WT (SCHEDULE) determine the inside diameter (ID) of a pipe, which determines the liquid capacity of the pipe. The NPS does not match the true diameter, it is a rough indication |

金属管子最重要的特征是外径和壁厚。这些参数一般用英寸或者毫米作为单位,标识的外径也就是实际外径。The most important dimensions for a steel tube are the outside diameter (OD) and the wall thickness (WT). These parameters are expressed in inches or millimeters and express the true dimensional value of the hollow section. |

| Wall Thickness 壁厚 |

金属管的壁厚会被指定一个"schedule"值 (最常见的是 sch.40,Sch. STD., Sch. XS, Sch. XXS等等)。两种公称管径不一样的管但有同样的 schedule值时,其壁厚不一样。The thickness of a steel pipe is designated with a "Schedule" value (the most common are Sch. 40, Sch. STD., Sch. XS, Sch. XXS). Two pipes of different NPS and same schedule have different wall thicknesses in inches or millimeters. |

The wall thickness of a steel tube is expressed in inches or millimeters. For tubing, the wall thickness is measured also with a gage nomenclature. |

| Types of Pipes and Tubes (Shapes) 形状 |

Round only 仅圆管 |

Round, rectangular, square, oval 圆形、矩形、方形、椭圆形 |

| Production range 量产规格的范围 |

Extensive (up to 80 inches and above) 可以高到80英寸和更高 |

A narrower range for tubing (up to 5 inches), larger for steel tubes for mechanical applications 范围较窄,最高只有5英尺 |

| Tolerances (straightness, dimensions, roundness, etc) and Pipe vs. Tube strength 公差 |

Tolerances are set, but rather loose. Strength is not the major concern. 设置有公差,但比较宽松,强度不是主要的考虑点。 |

金属管子则有严格公差。管子需要在制造的过程中对各方面的尺寸进行质检,比如直度,圆度,壁厚,以及检查表面等等。机械强度是管子的主要考虑点。Steel tubes are produced to very strict tolerances. Tubulars undergo several dimensional quality checks, such as straightness, roundness, wall thickness, surface, during the manufacturing process. Mechanical strength is a major concern for tubes. |

| Production Process 生产工艺 |

管一般是由高度自动化的高效工艺来批量生产的,比如管厂一般连续生产并将其分销到全球各地。Pipes are generally made to stock with highly automated and efficient processes, i.e. pipe mills produce on a continuous basis and feed distributors stock around the world. |

管子的制造流程更长并且消耗更多人工 Tubes manufacturing is more lengthy and laborious |

| Delivery time 交期 |

Can be short 短 |

Generally longer 长 |

| Market price 市场价格 |

比管子相对低 Relatively lower price per ton than steel tubes |

高,由于生产成本和严格的要求 Higher due to lower mills productivity per hour, and due to the stricter requirements in terms of tolerances and inspections |

| Materials 材料 |

可选的材料很多 A wide range of materials is available |

管子主要采用碳钢,低碳合金,不锈钢,镍合金,一般的机械方面应用使用的管子是碳钢的Tubing is available in carbon steel, low alloy, stainless steel, and nickel-alloys; steel tubes for mechanical applications are mostly of carbon steel |

| End Connections 连接方式 |

坡口,平口和螺纹 The most common are beveled, plain and screwed ends |

Threaded and grooved ends are available for quicker connections on site 螺纹和槽型以便于快速连接 |